湖北(bei)隆湖工程机械股份有限公司,歡迎(ying)您! 今(jin)天是(shi):

僅供(gong)個人(ren)參考(kao)

高性(xing)能密(mi)閉蝶(die)閥,普(pu)遍适(shi)用于(yu)建材(cai)、玻璃(li)、礦山(shan)、電力(li)、輕工(gong)、造紙(zhi)等行(hang)業的(de)通風(feng)、環保(bao)工程(cheng)等管(guan)道系(xi)統中(zhong)。對管(guan)道中(zhong)氣體(ti)介質(zhi)按不(bu)同控(kong)制信(xin)号調(diao)節流(liu)量大(da)小和(he)切斷(duan)。

This valve is widely used in the pipe system such as venting and environment protection in building material, glass, mining, power, light industry and papermaking departments. It can change the flow and cut off gas medium in the pipe by the different control signal.

結構(gou)特點(dian):

Structure characteristic:

高性(xing)能密(mi)閉蝶(die)閥具(ju)有重(zhong)量輕(qing)、結構(gou)緊湊(cou)、耐磨(mo)損、流(liu)阻損(sun)失小(xiao)、工作(zuo)壓力(li)高、密(mi)封壓(ya)差大(da)、操作(zuo)靈活(huo)、指示(shi)方位(wei)明确(que)、維護(hu)方便(bian)、使用(yong)壽命(ming)長等(deng)優點(dian)。可任(ren)意角(jiao)度安(an)裝,特(te)别适(shi)用于(yu)調節(jie)切斷(duan)和要(yao)求快(kuai)速自(zi)保的(de)場合(he)。配用(yong)DKJ、ZKJ、伯納(na)德等(deng)電動(dong)執行(hang)器及(ji)有關(guan)配件(jian),可實(shi)現手(shou)動、自(zi)動無(wu)幹擾(rao)切換(huan),微機(ji)程控(kong)、自動(dong)控制(zhi)或中(zhong)央集(ji)中控(kong)制,是(shi)實現(xian)自動(dong)化控(kong)制操(cao)作、調(diao)節流(liu)✨量的(de)理想(xiang)設備(bei)。

The valve has the features of lightweight, compact structure, endurance, little in the lost of flow resistance, high working pressure, flexible operation, definite direction, easy to maintenance and long life. It can be installed at any angle. It is suitable in the condition of adjusting, cutting off and self-protecting quickly. The valve is used with DKJ, ZKJ, Bernard electric actuator and other accessory to form a complete set to realize manual and automatic exchange without interference, micro-computer long-range control, automatic control or center concentrating control. It is the ideal equipment of realizing operation of automatic control and adjusting flow.

性能(neng)參數(shu):

Performance parameter:

Nominal pressure (MPa) | 0.25 | 0.6 | 1.0 | 1.6 | 2.5 | |

密封(feng)試驗(yan)壓力(li)Seal test pressure (MPa) | 0.66 | 1.1 | 2.75 | |||

強度(du)試驗(yan)壓力(li)Strength test pressure (MPa) | 0.9 | 1.5 | 3.75 | |||

适用(yong)溫度(du)Suitable temperature | ||||||

使用(yong)介質(zhi)Suitable medium | 空氣(qi)、煙氣(qi)、粉塵(chen)氣體(ti)等 Air, smoke, gas with powder etc | |||||

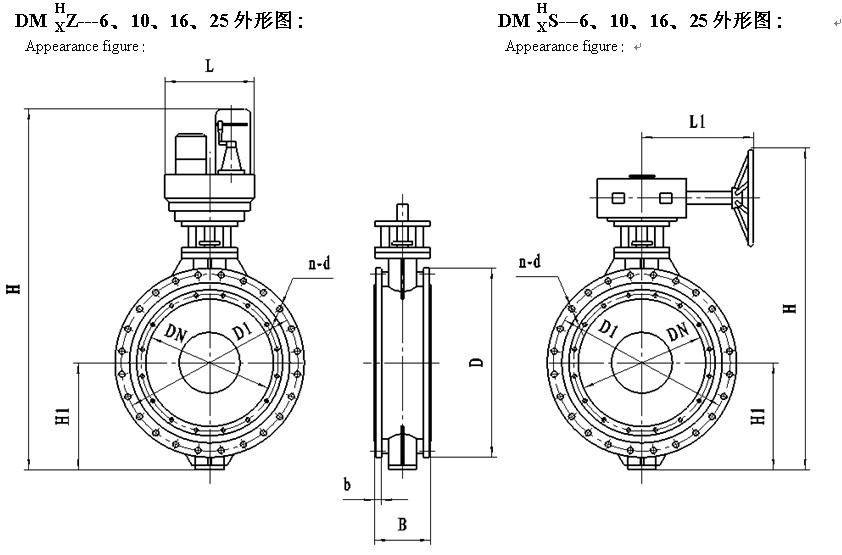

DM H X Z S---6、10、16、25外(wai)形連(lian)接尺(chi)寸:

Appearance joint dimensions:

DN | PN | D | D1 | B | b | n-d | H | H1 | L | L1 | 執(zhi)行器(qi)參數(shu) Parameter |

50 | 0.6 | 110 | 45 | 4-Φ14 | 100 | 90 | 310 | DKJ-210 | |||

1.0 | 165 | 20 | 4-Φ18 | 490 | 90 | 310 | |||||

1.6 | 165 | 125 | 20 | 4-Φ | 490 | 90 | |||||

2.5 | 165 | 45 | 20 | 4-Φ | 100 | 90 | |||||

80 | 0.6 | 190 | 150 | 48 | 18 | 125 | 310 | DKJ-210 | |||

1.0 | 200 | 160 | 45 | Φ18 | 520 | 125 | 90 | 310 | |||

1.6 | 200 | 160 | 20 | 8-Φ18 | 125 | 90 | |||||

2.5 | 200 | 24 | 8-Φ18 | 125 | 90 | 310 | |||||

100 | 0.6 | 210 | 170 | 52 | 18 | 540 | 142 | 310 | DKJ-310 | ||

180 | 22 | 8-Φ18 | 540 | 310 | |||||||

1.6 | 220 | 180 | 52 | 22 | 8-Φ18 | 580 | 145 | 90 | 310 | ||

235 | 190 | 52 | 24 | 8-Φ22 | 580 | 145 | 90 | 310 | |||

125 | 0.6 | 200 | 54 | 20 | 8-Φ | 565 | 155 | 90 | DKJ-310 | ||

1.0 | 210 | 54 | 22 | Φ18 | 565 | 90 | 310 | ||||

250 | 210 | 54 | 22 | 8-Φ18 | 160 | 90 | 310 | ||||

2.5 | 220 | 54 | 26 | 8- | 160 | 90 | 310 | ||||

150 | 0.6 | 265 | 225 | 56 | 20 | 182 | 90 | 310 | |||

1.0 | 285 | 56 | 24 | 8-Φ22 | 180 | 90 | 310 | ||||

1.6 | 285 | 240 | 670 | 190 | 90 | 310 | DKJ-410 | ||||

2.5 | 300 | 250 | 28 | Φ26 | 670 | 190 | 310 |

DN | PN | D | D1 | B | n-d | H | L1 | 執行(hang)器參(can)數 Parameter | |||

200 | 280 | 60 | 22 | 8-Φ18 | 210 | 120 | 380 | ||||

295 | 60 | 24 | 210 | 120 | 380 | DKJ-310 | |||||

340 | 295 | 60 | 795 | 220 | 120 | 380 | DKJ-410 | ||||

360 | Φ26 | 160 | 485 | DKJ-510 | |||||||

0.6 | 375 | 335 | 68 | 24 | 12-Φ18 | 815 | 235 | 380 | DKJ-410 | ||

1.0 | 395 | 350 | 12-Φ22 | 815 | 235 | 120 | 380 | ||||

1.6 | 405 | 68 | 12-26 | 851 | 248 | 120 | 380 | DKJ-510 | |||

370 | 68 | 32 | 931 | 248 | 160 | 485 | |||||

300 | 0.6 | 440 | 395 | 78 | 24 | 925 | 250 | 160 | 485 | DKJ-410 | |

1.0 | 78 | 12-Φ22 | 925 | 250 | 485 | DKJ-410 | |||||

460 | 410 | 12-Φ26 | 975 | 270 | 160 | 485 | DKJ-510 | ||||

2.5 | 485 | 78 | 16-Φ | 1045 | 270 | 205 | 570 | ||||

350 | 0.6 | 490 | 78 | 24 | 12-Φ22 | 975 | 160 | 485 | |||

1.0 | 505 | 78 | 26 | 16-Φ22 | 975 | 280 | 160 | ||||

1.6 | 520 | 470 | 78 | 30 | 16-Φ26 | 1039 | 302 | 160 | 485 | DKJ-610A | |

555 | 78 | 38 | 16-33 | 1109 | 302 | 205 | 570 | DKJ-610 | |||

400 | 0.6 | 540 | 495 | 102 | 24 | 16-Φ | 1129 | 312 | DKJ-510 | ||

515 | 102 | 16-26 | 1129 | 312 | 205 | 570 | DKJ-510 | ||||

1.6 | 580 | 102 | 16-Φ30 | 1220 | 353 | 225 | DKJ-610A | ||||

2.5 | 620 | 550 | 102 | 1220 | 335 | 620 | DKJ-610 | ||||

450 | 550 | 24 | 16-Φ | 1179 | 337 | 570 | |||||

1.0 | 615 | 565 | 114 | 28 | 20-Φ26 | 1179 | 337 | 205 | 570 | DKJ-510 | |

1.6 | 34 | 20-30 | 1260 | 355 | 225 | 620 | DKJ-610A | ||||

670 | 600 | 42 | 1360 | 355 | 620 | DKJ-610 | |||||

500 | 0.6 | 645 | 127 | Φ22 | 1229 | 370 | 205 | 570 | |||

1.0 | 620 | 127 | 28 | 20-Φ26 | 1229 | 205 | 570 | DKJ-610A | |||

600 | 755 | 705 | 154 | 26 | 20-Φ | 425 | 225 | DKJ-610A | |||

1.0 | 780 | 725 | 154 | 30 | 20-Φ30 | 225 | 680 | DKJ-610 | |||

0.6 | 165 | 26 | 24-Φ26 | 1570 | 488 | 225 | DKJ-610A | ||||

1.0 | 895 | 840 | 165 | 24-Φ30 | 1570 | 488 | 225 | DKJ-610 | |||

800 | 0.6 | 920 | 190 | 26 | 24-Φ30 | 1810 | 555 | 350 | 980 | ||

1010 | 950 | 32 | 555 | 350 | 980 | ||||||

0.6 | 1075 | 216 | 26 | 24-Φ30 | 1890 | 605 | 350 | DKJ-610 | |||

1.0 | 1050 | 216 | 34 | 28-Φ33 | 1890 | 350 | 980 | DKJ-710 | |||

0.6 | 216 | 26 | 28-30 | 665 | 350 | DKJ-610 | |||||

1160 | 34 | 28-Φ36 | 2005 | 665 | 350 | DKJ-710 | |||||

1200 | 1405 | 1340 | 240 | 32-Φ | 2080 | 970 | 380 | 1150 | |||

1400 | 0.6 | 1560 | 240 | 32 | 36-Φ36 | 2150 | 1050 | 1150 | |||

1500 | 0.6 | 240 | 32 | 36-Φ34 | 2230 | 1150 | DKJ-710 | ||||

1600 | 0.6 | 1830 | 1760 | 240 | 34 | 1200 | 380 | 1150 |

Working principle

采(cai)用雙(shuang)偏心(xin)密封(feng)結構(gou),關閉(bi)時越(yue)關越(yue)緊,開(kai)啟後(hou)确保(bao)密封(feng)面與(yu)密封(feng)圈完(wan)全脫(tuo)離接(jie)觸,保(bao)護密(mi)封圈(quan)不受(shou)損傷(shang),延♋長(zhang)使用(yong)壽命(ming)。密💃封(feng)面、密(mi)封圈(quan)選用(yong)不鏽(xiu)鋼㊙️制(zhi)作,其(qi)耐鏽(xiu)蝕、耐(nai)高溫(wen)性保(bao)證了(le)密封(feng)🏃♀️性能(neng)的可(ke)靠。采(cai)用半(ban)軸結(jie)構,蝶(die)闆為(wei)桁架(jia)式🌈結(jie)構,其(qi)強度(du)高、過(guo)流面(mian)積大(da)、流阻(zu)小、節(jie)省能(neng)源。本(ben)閥具(ju)有介(jie)質雙(shuang)向截(jie)止🏒密(mi)封功(gong)能,其(qi)滲漏(lou)量為(wei)零。

自(zi)動高(gao)性能(neng)密閉(bi)蝶閥(fa);由電(dian)動執(zhi)行器(qi)接受(shou)變送(song)、調節(jie)❓DCS、PLC等上(shang)位儀(yi)表的(de)控制(zhi)信号(hao)或操(cao)作器(qi)手控(kong)信号(hao),輸出(chu)角位(wei)移🍓帶(dai)動傳(chuan)動軸(zhou),把🧡動(dong)力傳(chuan)給閥(fa)軸帶(dai)動蝶(die)闆作(zuo)同步(bu)旋轉(zhuan)運動(dong),達到(dao)📱全開(kai)、全閉(bi)及任(ren)意調(diao)節的(de)目🏃♂️的(de)。電動(dong)執行(hang)器與(yu)蝶闆(pan)的開(kai)度同(tong)步反(fan)饋0~10mA或(huo) 4~20mA直流(liu)電🐪信(xin)号,用(yong)戶可(ke)根據(ju)電流(liu)信号(hao)來控(kong)制蝶(die)💞闆的(de)任意(yi)開度(du),達到(dao)調節(jie)的目(mu)的。

The valve adopts double eccentric sealed structure. The more it is close, the more it is tight. The sealing surface will separate from sealing ring, which prevent the sealing ring from damaging. The material of sealing surface and ring is stainless steel whose resistance of abrasion and high temperature ensure the reliability of sealing performance. It adopts half shaft structure and the butterfly disc is trussed structure, having the features of great strength, big flow area, little lost of flow resistance and saving energy. The valve has the function of stopping and sealing medium in double directions and without leakage.

Manual high performance sealed butterfly valve: rotate hand wheel to drive the valve axle and butterfly disc rotate in the range of 90°to cut off, connect or adjust the flow. The open or close position of the valve gate is limited by the limit device. The indicating device displays the position of butterfly disc.

安(an)裝及(ji)調試(shi):

Installation and regulation

l 安裝(zhuang)前必(bi)須清(qing)潔閥(fa)體内(nei)腔,不(bu)允許(xu)有任(ren)何雜(za)物和(he)👨❤️👨污垢(gou)附着(zhe)(特别(bie)注意(yi)密封(feng)面、密(mi)封圈(quan)的清(qing)潔)。

l 水(shui)平安(an)裝或(huo)垂直(zhi)安裝(zhuang)的閥(fa)門閥(fa)軸應(ying)處于(yu)水平(ping)位置(zhi),傳動(dong)裝置(zhi)不允(yun)許作(zuo)起吊(diao)用,并(bing)嚴禁(jin)損傷(shang)。

l 本閥(fa)具有(you)一定(ding)的雙(shuang)向密(mi)封性(xing)能,若(ruo)隻需(xu)控制(zhi)單方(fang)向❤️流(liu)🍉動的(de)㊙️介質(zhi)時,其(qi)安裝(zhuang)方向(xiang)應參(can)照閥(fa)體上(shang)箭頭(tou)所示(shi),該箭(jian)頭所(suo)⭐指為(wei)介質(zhi)🙇♀️流向(xiang)。

l 安裝(zhuang)如示(shi)意圖(tu),加密(mi)封墊(nian)後均(jun)勻鎖(suo)緊聯(lian)接螺(luo)栓。

l 調(diao)整完(wan)成後(hou)必須(xu)進行(hang)綜合(he)性能(neng)檢查(cha):接通(tong)電源(yuan)開啟(qi)閥門(men),當📐閥(fa)門至(zhi)“全開(kai)”“全閉(bi)”位置(zhi)時,行(hang)程控(kong)制機(ji)構🌍應(ying)準确(que)地切(qie)斷電(dian)源,而(er)轉矩(ju)限位(wei)機構(gou)處于(yu)臨界(jie)動作(zuo)狀态(tai)🌍。開度(du)指示(shi)機構(gou)應準(zhun)确地(di)顯示(shi)閥門(men)的開(kai)啟狀(zhuang)态。

l 電(dian)動切(qie)換手(shou)動操(cao)作時(shi),應切(qie)斷電(dian)源,不(bu)得在(zai)手輪(lun)上再(zai)⛹🏻♀️增加(jia)💘輔助(zhu)杠杆(gan),手輪(lun)順時(shi)針旋(xuan)轉為(wei)關,反(fan)之為(wei)開,閥(fa)闆開(kai)啟角(jiao)度為(wei)0°~90°。

l The body must be cleaned before installed and there is no dirt and sundries clinging to the body, especially the sealing surface and ring.

l The valve has the feature of double-sealing performance. The installation direction should refer to the arrow on the valve body, which indicates the medium flow direction, when control the flow of medium in single direction.

l Installation of flange connecting valve is on diagram. Lock down the connecting bolt after add sealing washer.

l Synthetic performance of the valve must be done after adjust is over: turn on the power and open the valve, the stroke control device should cut down the power exactly when the valve is in the state of full open or full close. While the torque limit device is in critical state. The open angle indicating device should display the open state of the valve gate exactly.

l The power must be shut down when operating by manual. Assistant pole can’t be added to hand wheel. Clockwise rotation of hand wheel means open and anticlockwise means close. Open angle is 0~90°.

運輸(shu)及保(bao)管:

Transportation and protection

l 運(yun)輸時(shi)應避(bi)免撞(zhuang)擊蝶(die)閥及(ji)傳動(dong)裝置(zhi),閥門(men)應處(chu)于❄️全(quan)♉閉位(wei)置,以(yi)防在(zai)運輸(shu)中密(mi)封面(mian)和傳(chuan)動部(bu)件損(sun)壞。

l 當(dang)閥門(men)水平(ping)放置(zhi)運輸(shu)時,傳(chuan)動裝(zhuang)置及(ji)傳動(dong)部位(wei)應懸(xuan)🔴空,以(yi)防止(zhi)傳動(dong)軸受(shou)力過(guo)大而(er)變形(xing)損壞(huai)。

l 該閥(fa)應存(cun)放在(zai)幹燥(zao)的室(shi)内,不(bu)允許(xu)露天(tian)存放(fang)或堆(dui)🔞置。長(zhang)期存(cun)放時(shi)應使(shi)閥門(men)處于(yu)關閉(bi)狀态(tai),各傳(chuan)動部(bu)位加(jia)潤滑(hua)油,傳(chuan)動裝(zhuang)📐置作(zuo)防潮(chao)、防塵(chen)處理(li)。

l Avoid bumping of valve and transmission device. The valve is in full close in order to avoid damage of sealing surface and driving part.

Maintenance and examination

l 定期(qi)給閥(fa)的傳(chuan)動部(bu)位加(jia)潤滑(hua)油。

l Check the working condition of electric parts, control switch and sealing of pneumatic device regularly.

訂貨(huo)須知(zhi):

Information for order

l 選用(yong)訂貨(huo)時,請(qing)參照(zhao)産品(pin)樣本(ben)注明(ming)産品(pin)規格(ge)、型号(hao)、客戶(hu)🔞選用(yong)執行(hang)器代(dai)号及(ji)技術(shu)參數(shu)(使用(yong)溫度(du)、設備(bei)工況(kuang)🧑🏽🤝🧑🏻、介質(zhi)性質(zhi)等)。

l 選(xuan)用訂(ding)貨時(shi),若未(wei)注明(ming)客戶(hu)選用(yong)傳動(dong)裝置(zhi)代号(hao)的🌍按(an)我公(gong)🈲司基(ji)本型(xing)配置(zhi),其基(ji)本型(xing)為普(pu)通型(xing)裝置(zhi),不帶(dai)任何(he)有關(guan)特殊(shu)要求(qiu)及相(xiang)關配(pei)件。基(ji)本的(de)傳動(dong)裝置(zhi)、電氣(qi)裝置(zhi)為普(pu)通型(xing),如有(you)其他(ta)特殊(shu)💞要求(qiu)(戶外(wai)、微⛷️控(kong)、防爆(bao)等❤️)請(qing)在合(he)同🏃🏻♂️中(zhong)注明(ming)。

l 表中(zhong)未列(lie)的規(gui)格、用(yong)于特(te)殊介(jie)質或(huo)其它(ta)特殊(shu)要求(qiu),請與(yu)我公(gong)司經(jing)銷部(bu)、技術(shu)部聯(lian)系,可(ke)為您(nin)另行(hang)設計(ji)、制造(zao)。

l If you don’t indicate actuator code selected by user when you place an order, we will select the basic collocation of our company for you. The basic type is a normal type without any special request and corresponding accessory. The basic transmission device and electricity device is normal type. If you have especial demand (anti-explosion, outdoors and micro control etc), please indicate in the contract.

l If you have other special demand, need special medium or the data that is not listed in the table, please contact with our department of market and technology. We can design and manufacture for you especially.