保能高(gao)溫蝶閥(fa)系環保(bao)節能型(xing)産品,能(neng)充分利(li)用熱能(neng)有效治(zhi)理煙氣(qi)。适用于(yu)建材、玻(bo)璃、礦山(shan)、電力等(deng)行業的(de)熱風管(guan)道🌂系統(tong)中。對管(guan)道中氣(qi)體介質(zhi)按不同(tong)🌍控制信(xin)号調節(jie)流量大(da)小和切(qie)斷。

結構(gou)特點:

保(bao)能高溫(wen)蝶閥,采(cai)用超強(qiang)度熱強(qiang)鋼、不鏽(xiu)鋼、優質(zhi)碳👅鋼焊(han)💚接,内🌈襯(chen)㊙️熱強鋼(gang)及保溫(wen)材料層(ceng)。具有耐(nai)高溫、耐(nai)磨損、剛(gang)性強、流(liu)阻損失(shi)小、熱損(sun)失小、保(bao)溫效率(lü)高、操作(zuo)靈活、指(zhi)示方位(wei)明确、維(wei)護方便(bian)、使用壽(shou)命長等(deng)優點。可(ke)水平安(an)裝或垂(chui)直安裝(zhuang)。配用DKJ、ZKJ、伯(bo)納德等(deng)電動執(zhi)⁉️行器及(ji)有關配(pei)件,可實(shi)現手動(dong)、自動無(wu)🏃♂️幹擾切(qie)換,微機(ji)程控、自(zi)動控制(zhi)或中央(yang)集中控(kong)制,是實(shi)現自🍓動(dong)化控制(zhi)操作、調(diao)節流量(liang)的理想(xiang)設備。

The valve is welded in high strength heat-resistant steel, stainless steel and fine carbon steel, having stainless steel lining and preserving heat material layer. It is high-temperature resistance, high in strength, endurance, little in the lost of the thermal energy and flow resistance, efficient in saving thermal energy, handy to operate, definite direction, easy to maintenance and long life. It can be installed in horizontal or vertical. The valve is used with DKJ, ZKJ, Bernard electric actuator and other accessory to form a complete set to realize manual and automatic exchange without interference, micro-computer long-range control, automatic control or center concentrating control. It is the ideal equipment of realizing operation of automatic control and adjusting flow.

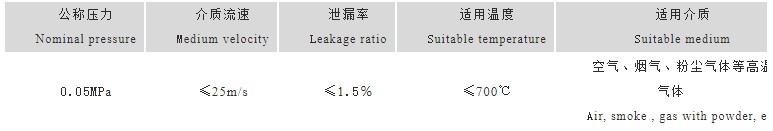

性(xing)能參數(shu):

Performance parameter:

ZBGD---700外形連(lian)接尺寸(cun):

Appearance joint dimensions:

D | D1 | B | b | E | L1 | L2 | Parameter | ||

180 | 10 | Φ14 | 1030 | 620 | DKJ-210 Tm P:0.025KW | ||||

150 | 450 | 405 | 180 | 16-Φ14 | 1080 | 450 | |||

200 | 500 | 455 | 180 | 10 | 1250 | 450 | 620 | ||

250 | 50 | 505 | 180 | 16-Φ14 | 1270 | 450 | 620 | ||

620 | 565 | 180 | 12 | 20-Φ | 1335 | 620 | |||

615 | 12 | 20-18 | 1385 | 500 | T:0N·m P:0.065KW | ||||

400 | 720 | 665 | 220 | 12 | Φ18 | 1760 | |||

770 | 715 | 220 | 12 | 20-Φ | 500 | 650 | |||

500 | 820 | 220 | 12 | 20-Φ18 | 500 | 650 | |||

600 | 930 | 16 | 24-Φ22 | 70 | DKJ-410 T:600N· P:0.16KW | ||||

700 | 1030 | 970 | 260 | 16 | 24-Φ22 | 2180 | 600 | 700 | |

800 | 1130 | 1070 | 260 | 16 | 2280 | 600 | |||

900 | 1230 | 300 | 16 | 28-Φ22 | 2380 | 820 | DKJ-510 T:0N·m | ||

1000 | 1330 | 1270 | 300 | 16 | 28-Φ22 | 2480 | 620 | 820 | |

1100 | 1430 | 1370 | 300 | 16 | 620 | 820 | |||

1200 | 1530 | 300 | 16 | 36-Φ22 | 2700 | ||||

1300 | 1630 | 1570 | 300 | 16 | 36-Φ22 | 2870 | 820 | ||

1400 | 1730 | 300 | 40-Φ22 | 2970 | 620 | 820 | |||

1500 | 1830 | 340 | 20 | 40-22 | 650 | DKJ-610A T:250m P:0.65KW | |||

1600 | 1930 | 340 | 20 | 44-22 | 3290 | 900 | |||

2030 | 1970 | 340 | 20 | 650 | 900 | ||||

1800 | 2130 | 2070 | 650 | 900 | |||||

1900 | 2230 | Φ22 | 650 | 1000 | DKJ-610 | ||||

2000 | 2330 | 2270 | 380 | 48-Φ22 | 3710 | 650 | 1000 | ||

2100 | 2370 | 380 | 20 | 48-22 | 3810 | 650 | 1000 | ||

2470 | 20 | 22 | 3930 | 650 | 00 | ||||

2650 | 2585 | 380 | 24 | 4030 | 650 | 1000 | |||

2400 | 2750 | 2685 | 380 | 24 | 52-Φ | 650 | 1000 | ||

2500 | 2785 | 24 | 56-Φ26 | 4250 | 750 | 1350 | DKJ-710 T:6000N·m 1.0KW | ||

2950 | 2885 | 420 | 24 | 750 | 1350 | ||||

2700 | 3050 | 420 | 60-26 | 4450 | 1350 | ||||

3150 | 24 | 60-Φ26 | 1350 | ||||||

2900 | 3250 | 3185 | 420 | 24 | 64-Φ26 | 4650 | 1350 | ||

3000 | 3350 | 420 | 24 | 64-Φ26 | 4750 | 750 | 1350 |